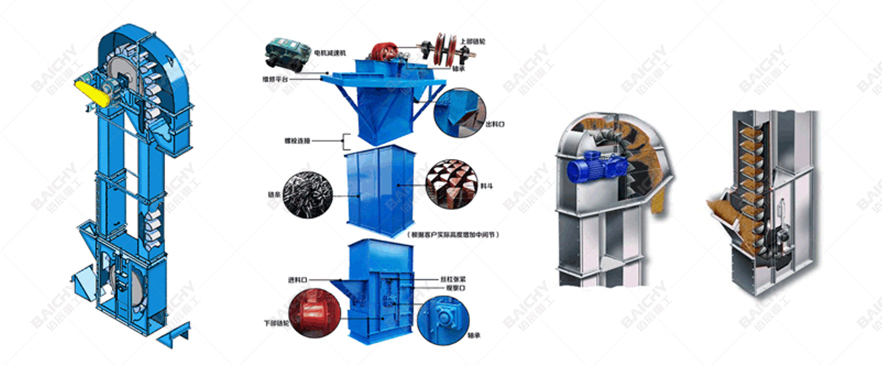

Bucket elevator is a continuous conveying machine widely used for material lifting and transportation. A bucket elevator is a device that uses a series of buckets evenly fixed to an endless traction member (such as a chain or belt) to transport bulk materials upward in a vertical or nearly vertical direction.

Mining and mining industry: used for lifting and conveying coal, ore, metal ore, etc.

Metallurgy and smelting industry: used for lifting and conveying raw materials and by-products such as iron ore, coke, limestone, etc.

Building materials industry: used for lifting and conveying building materials such as cement, sandstone, gypsum, etc.

The bucket elevator adopts the inflow feeding method, and there will be no extrusion and collision between the materials, which reduces the wear and tear of the machine.

With a capacity of 34-1112 m³/h, our bucket elevators can convey large quantities of free-flowing materials as well as many materials with poor fluidity with high conveying efficiency.

The bucket elevator transports materials in the vertical direction and has a compact and simple structure, so it occupies a small area and greatly saves the area occupied.

The bucket elevator has good sealing performance, and the conveying work is carried out in a fully enclosed body without dust leakage, clean and environmentally friendly.

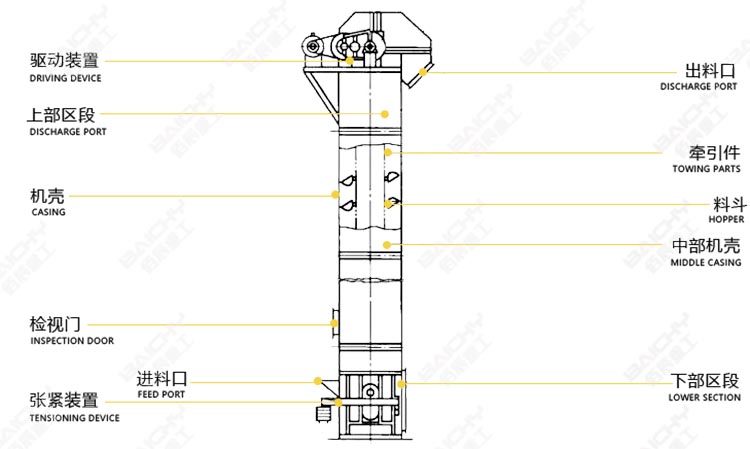

A bucket elevator consists of a hopper, a drive, top and bottom rollers (or sprockets), belts (or traction chains), tensioning devices, and a casing.

Driven by the driving device, the material reaches the top with the conveyor belt, bypasses the top wheel, and turns downwards, and then the material is discharged from the discharge port under the action of centrifugal force or gravity and sent to the next process.

| Model | T160 | T250 | T315 | T400 | T500 |

|---|---|---|---|---|---|

| Bucket Width(mm) | 160 | 250 | 315 | 400 | 500 |

| Bucket Distance(mm) | 300 | 420 | 500 | 560 | 625 |

| Speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | 1.8 |

| Max Granule size(mm) | 25 | 35 | 45 | 55 | 60 |

| Height(m) | H+0.9 | H+1.2 | H+1.2 | H+1.5 | H+1.5 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery